Baseball’s loss of Don Perigny eventually became procurement’s gain.

It’s a “long story,” he says, but this covers the bases: Following his third year in college, Perigny was signed in August 1990 by the Chicago White Sox. After three seasons moving up in the minor leagues, he was MLB Rule 5 traded to the Florida Marlins. Playing at the AAA level, he was told he was on track to make it to “the show” (that’s the major leagues, for those who haven’t seen Bull Durham).

Then came the 1994-95 players’ strike, which lasted 232 days and caused the cancellation of the 1994 World Series. Perigny refused multiple offers by the club to cross the picket line and play with the Marlins along with other recruited replacement players.

“I thought, ‘I worked too hard to take any shortcuts now,’” he recalls. “Five weeks into season, they let me go. At that moment, it stopped being a game and became a business. I returned home and never looked back.”

Fortunately, a different kind of team was very interested in him. In the off seasons, Perigny had been working at a scanning electron microscope company. When he was released by the Marlins in 1995, the company’s owner reached out to him and said, “I heard how you were let go. You have integrity. You’re the type of person I want working for me. I’ll pay for you to finish school. When something better comes along, you go.”

Within a year, Perigny was in charge of his department. The company’s vice president then told him about an opening in purchasing. Though Perigny said he knew nothing about purchasing, he was told, “You’ll figure it out. You start Monday.” Within a year, he was running that department.

“I can be happy doing anything. I’m an optimist.”

Don Perigny

Perigny was an MVP wherever he worked. “I can be happy doing anything,” he says. “I’m an optimist. My father was a lunatic about working with purpose. He used to tell me that two things can happen when you go on vacation: either they miss you or they don’t. So go on vacation, but when you return to work, make sure you’re ready to go.”

Twenty years ago, he came to Werfen, a worldwide leader in hemostasis testing, with worldwide annual sales exceeding $2 billion. Perigny is the director of supply chain. “There is nothing about my job or the people with whom I work that I don’t like,” he says. “One thousand people in the building and there are no impossible people. How do you create a culture like that where people work together as well as we do?”

That’s something of a softball question for Perigny. His years in minor league baseball, he says, grounded him in a team mentality. “You learn how to work and get along with people when you’re stuck on a bus with them,” he jokes. “You gain an understanding of different personalities.”

From former mentors and managers, he retained these pieces of advice: “Pay attention to the little things. Be prepared. Fix the little issues before they become big problems. Take care of the suppliers that take care of you.”

Perigny’s own team consists of twenty-two people working in a variety of areas, including procurement, supplier engineering, and materials coordination. The watchwords of his leadership style, he says, are communication, teamwork, and ownership. “We’re going to succeed or fail as a team,” he says. “Owning your own piece is key.”

Presently, Werfen ships 200-220 hemostasis instruments per month, which represents a sizeable share of their business. Another significant piece of business is in acute care diagnostics, including point-of-care blood testing instruments. “We became quite instrumental in the COVID fight worldwide,” he says.

During the height of the pandemic, Perigny states with pride, “We proved we were up to the challenge. We have such an amazing supply chain. We refused to fail at supplying hospitals and laboratories with everything they needed. We changed and adapted to the times. This is what we do, and we’re pretty good at it.”

“There is nothing about my job or the people with whom I work that I don’t like. One thousand people in the building and there are no impossible people.”

Don Perigny

The primary challenge of his role, he says, is being proactive. “We can’t react too slow to issues, or we’ll be at the back of the line for supply. Everything affects us: weather, de-commits from manufacturers, labor shortages, wood . . . everything.”

Moving forward, he says, nurturing supplier relationships always continue to come first. “This is what allowed us to succeed during the pandemic and will carry us into the future.”

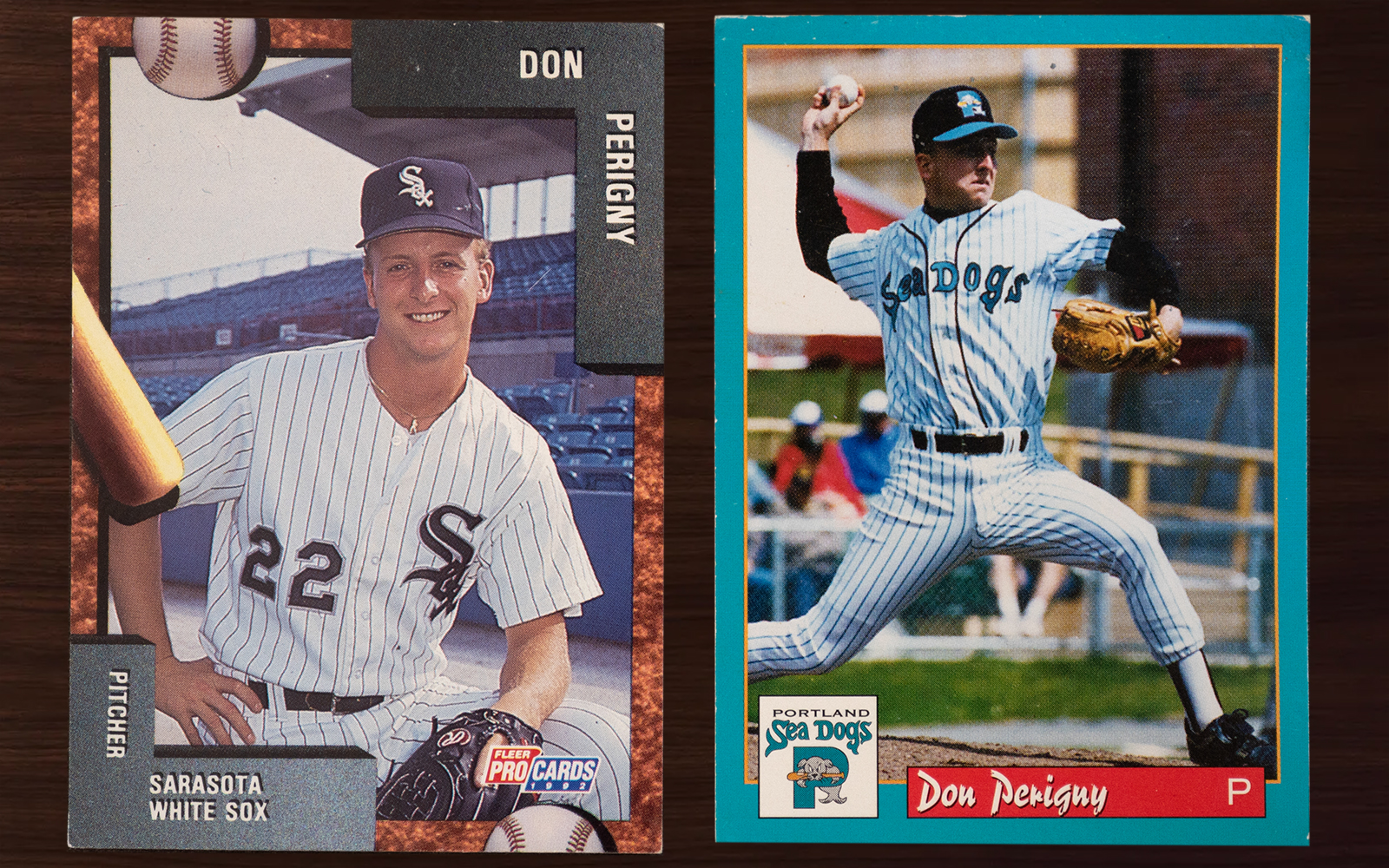

Perigny has his own baseball cards as a memento of his years as a player. “I don’t get to put on a baseball uniform anymore,” he says. “But I have no regrets. I’m celebrating my thirtieth wedding anniversary this year, and I have three wonderful sons, ages twenty-six, twenty-four, and twenty. I have the best job in the world, and I fight to be the best in my field, just like I did on the baseball diamond. Life is great for me.”

Custom Machine, is a world leader in precision manufacturing of Aerospace, Medical, Semi-Conductor and Commercial components and assemblies. We utilize advanced CNC Milling, Turning, Grinding, and EDM machines to manufacture complex geometry which requires multi-axis machining techniques. Our team of Engineers, Programmers and Machinists are experienced and innovative.